3D Bioprinting – The Future of Dental Implants and Prosthetics

The realm of dental implants and prosthetics has witnessed a remarkable evolution over the past few decades. From the early days of rudimentary replacements, we have transitioned to sophisticated, tailor-made solutions that not only restore functionality but also closely mimic the aesthetics of natural teeth. Today, dental implants and prosthetics have become an integral part of restorative dentistry, offering hope and improved quality of life to millions who have lost their natural teeth due to various reasons, be it decay, trauma, or congenital anomalies.

However, despite these advancements, there remain challenges. Traditional dental implants, while effective, can sometimes face issues like rejection, infection, or the need for replacement after a certain period. Prosthetics, too, have their limitations, especially when it comes to ensuring a perfect fit and replicating the natural feel of teeth.

Enter the world of technology, which has consistently demonstrated its potential to revolutionize healthcare sectors. One of the most promising technological advancements in recent years is 3D bioprinting. This innovative process, which involves creating functional, living tissues using bioinks, holds the potential to address many of the challenges faced by traditional dental implants and prosthetics. Imagine a future where dental replacements are not just made to fit but are biologically alive, integrating seamlessly with the patient’s body, reducing rejection rates, and offering a more natural feel.

As we stand on the cusp of this technological revolution, it’s essential to delve deeper into 3D bioprinting’s potential and understand how it’s set to redefine the landscape of dental implants and prosthetics.

Demystifying 3D Bioprinting

What is 3D bioprinting, and how does it work?

3D bioprinting is a groundbreaking technology that merges the principles of 3D printing with the complexities of biological structures. At its core, 3D bioprinting involves the layer-by-layer deposition of biological materials, often referred to as “bioinks,” to create tissue-like structures that imitate natural tissues in both form and function. These bioinks can be composed of various materials, including living cells, proteins, and biocompatible polymers.

The process begins with the creation of a digital blueprint or a 3D model, which is designed based on the desired tissue or organ’s anatomy. Specialized bioprinters then use this model as a guide, depositing the bioinks layer by layer. As these layers accumulate, they form a 3D structure. Post-printing, the structure undergoes a maturation process in a controlled environment, allowing the cells to grow, multiply, and form functional tissues.

How is it different from traditional 3D printing?

While 3D bioprinting and traditional 3D printing share foundational principles, they cater to vastly different applications and utilize distinct materials.

- Material Composition: Traditional 3D printing employs materials like plastics, metals, or ceramics. In contrast, 3D bioprinting uses bioinks, which are often a blend of living cells, growth factors, and biocompatible materials.

- Purpose: Traditional 3D printing is predominantly used for creating non-living objects, ranging from prototypes to functional parts. 3D bioprinting, on the other hand, aims to produce living tissues and organs for medical applications, such as transplantation, drug testing, or disease modeling.

- Post-Processing: Once an object is printed using traditional methods, it might undergo some finishing touches, but its core structure remains unchanged. In bioprinting, the post-printing phase is crucial. The printed structure often requires a nurturing environment, like a bioreactor, to allow cells to mature, interlink, and form a functional tissue.

- Precision & Complexity: The stakes in 3D bioprinting are incredibly high. The process demands extreme precision to ensure cellular viability and functionality. The complexity arises from the need to replicate the intricate microenvironments of natural tissues, ensuring cells receive adequate nutrients, oxygen, and signaling cues.

The Intersection of 3D Bioprinting and Dentistry

How is 3D bioprinting relevant to the field of dentistry?

The dental realm, with its intricate structures and specialized tissues, presents unique challenges that can greatly benefit from the precision and customization offered by 3D bioprinting. The mouth is not just a functional unit for mastication and speech but also plays a pivotal role in aesthetics and overall health. Ensuring the restoration or replacement of dental structures meets both functional and aesthetic demands is paramount.

3D bioprinting’s relevance in dentistry emerges from its ability to:

- Customization: Every individual’s oral anatomy is unique. 3D bioprinting can produce dental structures tailored to the exact specifications of a patient’s oral cavity, ensuring a perfect fit and natural appearance.

- Tissue Mimicry: Dental structures are not monolithic. Teeth, for instance, comprise layers with varying hardness and functionality. 3D bioprinting can replicate these multi-layered structures, ensuring the printed tooth isn’t just a block of material but mimics the natural tooth’s gradation from enamel to dentin to pulp.

- Regeneration: In cases of periodontal diseases, where there’s loss of gum tissue or even bone, 3D bioprinting can aid in regenerating these tissues using the patient’s cells, ensuring biocompatibility and reducing chances of rejection.

What potential does it hold for dental implants and prosthetics?

The fusion of 3D bioprinting with dental implants and prosthetics heralds a new era of dental restorations that are more natural, long-lasting, and harmonious with the patient’s biology.

- Bioactive Implants: Traditional dental implants are made of titanium or similar metals. While they are biocompatible, they are inert. 3D bioprinted implants can be designed with bioactive materials that not only anchor securely to the jawbone but also promote bone growth around the implant, ensuring better integration and longevity.

- Natural Prosthetics: Dental prosthetics like crowns, bridges, or dentures can be bioprinted to mimic the natural appearance of teeth, down to the translucency of enamel and the subtle color variations, making them indistinguishable from natural teeth.

- Bone and Gum Regeneration: In cases where patients lack the necessary bone density for implants, 3D bioprinting can be used to create scaffolds infused with growth factors to promote bone regeneration. Similarly, for patients with receding gums, bioprinted gum tissue can be grafted.

- Reduced Recovery Time: Since bioprinted implants and prosthetics can be designed to be bioactive and promote tissue integration, the healing and recovery time post-procedure can be significantly reduced.

- Future Innovations: As research progresses, there’s potential for bioprinting entire teeth complete with living pulp tissue, making root canals obsolete. Additionally, the combination of AI with 3D bioprinting could allow for predictive modeling, where dental professionals can foresee potential oral issues and create preventive prosthetics or interventions.

Advantages of 3D Bioprinted Dental Solutions

The world of dentistry is on the cusp of a revolution, with 3D bioprinting poised to play a pivotal role. As this technology becomes more integrated into dental practices, both patients and professionals stand to gain immensely. Let’s delve into the myriad benefits that 3D bioprinted dental solutions bring to the table.

How can patients benefit from 3D bioprinted dental implants and prosthetics?

- Customization to Perfection: Every individual’s oral structure is unique. 3D bioprinting allows for dental implants and prosthetics tailored to the exact specifications of a patient’s mouth. This ensures a more comfortable fit and natural appearance, enhancing the overall patient experience.

- Enhanced Durability: Bioprinted dental solutions are crafted with precision, leading to implants and prosthetics that are robust and long-lasting. Patients can expect fewer visits for adjustments or replacements.

- Reduced Recovery Time: Traditional dental implant procedures can be invasive, requiring significant recovery time. With 3D bioprinted implants, the procedure is less intrusive, leading to faster healing and reduced discomfort.

- Cost-Effective in the Long Run: While the initial investment might be higher, the longevity and reduced need for replacements or adjustments make 3D bioprinted solutions more cost-effective over time.

What are the advantages for dental professionals in adopting this technology?

- Precision and Accuracy: 3D bioprinting offers unparalleled precision, allowing dental professionals to craft implants and prosthetics with minute details. This reduces the margin of error and ensures a higher success rate for dental procedures.

- Efficiency and Productivity: Traditional methods can be time-consuming. With 3D bioprinting, dental professionals can produce multiple implants or prosthetics simultaneously, significantly cutting down production time.

- Innovation and Reputation: Adopting cutting-edge technology like 3D bioprinting can position a dental practice as a leader in the field. This not only attracts tech-savvy patients but also enhances the reputation of the practice.

- Continuous Learning and Development: The world of 3D bioprinting is ever-evolving. By integrating this technology, dental professionals can stay at the forefront of advancements, continuously updating their skills and knowledge.

The Process: From Design to Implant

The journey of a 3D bioprinted dental implant or prosthetic from conception to placement in a patient’s mouth is a marvel of modern technology. This intricate process combines the prowess of digital design with the precision of bioprinting, ensuring that the end product is both functional and biocompatible. Let’s break down the steps involved in this transformative procedure.

How are 3D bioprinted dental implants and prosthetics designed and created?

- Digital Imaging: The process begins with a comprehensive digital scan of the patient’s mouth. Advanced imaging techniques, such as intraoral scanners or CBCT (Cone Beam Computed Tomography), capture detailed 3D images of the oral cavity, highlighting the areas that require implants or prosthetics.

- Designing in CAD Software: Once the digital impression is obtained, it’s imported into specialized Computer-Aided Design (CAD) software. Dental professionals or trained technicians then design the implant or prosthetic, ensuring it aligns perfectly with the patient’s unique oral anatomy.

- Preparation for Printing: The designed model is then processed and converted into a format suitable for 3D bioprinting. This involves slicing the model into thin layers, which the printer will sequentially produce.

- 3D Bioprinting: The actual printing process involves depositing materials layer by layer to build the dental implant or prosthetic. Bioprinters use a syringe or nozzle to extrude the chosen biomaterial in a precise pattern, guided by the design from the CAD software.

- Post-Processing: After printing, the implant or prosthetic undergoes various post-processing steps, such as cleaning, sterilization, and sometimes curing (using light or heat to solidify the structure).

What materials are used, and how do they ensure compatibility and durability?

- Biocompatible Polymers: These are synthetic materials designed to interact safely with the human body. Examples include polylactic acid (PLA) and polyglycolic acid (PGA). They are often used as scaffolds that can degrade over time, allowing natural tissue to replace them.

- Hydrogels: These water-based gels can encapsulate living cells, making them ideal for applications where tissue regeneration is desired. They maintain a moist environment, promoting cell growth and function.

- Ceramics: Materials like hydroxyapatite or tricalcium phosphate mimic the mineral component of natural bone. They offer excellent durability and are often used in implants that require a rigid structure.

- Composite Materials: By combining the properties of polymers and ceramics, composite materials offer both strength and flexibility. They can be tailored to match the specific requirements of a dental application.

- Cell-laden Bioinks: These are advanced materials infused with living cells. When used in bioprinting, they can promote tissue regeneration, making them ideal for applications where natural integration with surrounding tissues is crucial.

Challenges and Concerns in 3D Bioprinting for Dentistry

The promise of 3D bioprinting in revolutionizing dental care is undeniable. However, like any pioneering technology, it comes with its own set of challenges and concerns that need to be addressed to ensure its widespread adoption and success. Let’s delve into some of the potential hurdles and the ethical considerations surrounding this groundbreaking technique.

What are the potential hurdles in adopting 3D bioprinting for dental solutions?

- Technical Limitations: While 3D bioprinting has made significant strides, there are still challenges related to achieving the precision required for intricate dental structures. Ensuring the printed structures have the right mechanical properties and can withstand the forces in the oral environment is crucial.

- Cost Implications: The initial investment in 3D bioprinting technology can be substantial. This includes not just the printers but also the specialized materials and training required. For many dental practices, especially smaller ones, this can be a deterrent.

- Regulatory Hurdles: Given that 3D bioprinting involves creating medical devices (implants and prosthetics), it’s subject to stringent regulatory scrutiny. Navigating these regulations and obtaining necessary approvals can be time-consuming.

- Skill Gap: The shift from traditional methods to a technology-driven approach requires training and upskilling. Dental professionals need to be acquainted with the nuances of design software, printer operation, and post-processing techniques.

- Material Challenges: While there’s a range of biocompatible materials available, finding the perfect material that’s both durable and promotes tissue integration for specific dental applications can be challenging.

Are there any safety or ethical concerns to be addressed?

- Patient Safety: As with any medical procedure, patient safety is paramount. Ensuring that the bioprinted implants and prosthetics are biocompatible, sterile, and free from contaminants is essential. Regular monitoring post-procedure is also crucial to detect any adverse reactions.

- Data Privacy: The digital design process involves creating detailed scans of a patient’s oral anatomy. Ensuring the security and privacy of this data is vital to prevent unauthorized access or breaches.

- Informed Consent: Patients need to be adequately informed about the procedure, the materials used, and any potential risks associated with 3D bioprinted dental solutions. Only with complete transparency can informed consent be obtained.

- Sustainability Concerns: As the adoption of 3D bioprinting grows, so will the consumption of printing materials. Ensuring that these materials are sourced sustainably and have minimal environmental impact is an ethical consideration.

- Equity in Access: Like many advanced medical technologies, there’s a risk that 3D bioprinting could widen the gap between those who can afford cutting-edge treatments and those who can’t. Addressing this disparity is crucial to ensure that the benefits of the technology are accessible to all.

Real-world Applications and Case Studies

The theoretical potential of 3D bioprinting in dentistry is vast, but it’s the real-world applications and success stories that truly underscore its transformative power. Across the globe, dental professionals and researchers are harnessing this technology to address complex challenges and deliver unparalleled patient outcomes. Let’s explore some of the ways 3D bioprinting is making a tangible difference in dental practices and delve into a few notable case studies.

How is 3D bioprinting currently being used in dental practices around the world?

- Custom Dental Implants: Traditional dental implants often come in standard sizes, requiring adjustments during surgery. With 3D bioprinting, implants are custom-designed to fit the patient’s unique anatomy, reducing surgery time and promoting better integration with the jawbone.

- Orthodontic Devices: Braces, retainers, and other orthodontic devices can be bioprinted to fit the patient’s teeth perfectly, ensuring comfort and efficacy.

- Full Arch Restorations: For patients with significant tooth loss, 3D bioprinting can create full arch restorations tailored to their oral cavity, restoring functionality and aesthetics.

- Bone Regeneration: In cases of bone loss in the jaw, 3D bioprinting can produce scaffolds infused with growth factors to promote bone regeneration, creating a stable foundation for future dental implants.

- Tissue Engineering: For patients with gum disease or tissue damage, bioprinted gum tissue can be used for grafting, promoting healing and restoring gum health.

Are there any notable success stories or breakthroughs?

- The World’s First 3D Printed Tooth: A few years ago, researchers unveiled the world’s first 3D printed tooth made of antimicrobial resin. This tooth not only fits perfectly but also kills bacteria, potentially reducing the risk of secondary cavities.

- Bioprinted Gums and Bone: In a groundbreaking procedure, a patient with significant bone and gum loss underwent successful grafting using 3D bioprinted bone and gum tissue, marking a significant advancement in regenerative dentistry.

- Customized Root Canal Therapy: A dental clinic in Europe utilized 3D bioprinting to create a custom mold for a patient undergoing root canal therapy. This mold accurately replicated the patient’s root canal anatomy, allowing for precise treatment and reduced recovery time.

- Training and Education: A dental school in Asia introduced 3D bioprinted dental models, replicating various dental conditions. These models serve as invaluable tools for students, allowing them to practice procedures in a risk-free environment before treating actual patients.

- Full Mouth Reconstruction: In a remarkable case, a patient who had lost most of his teeth due to a genetic condition received a full set of 3D bioprinted teeth, restoring his ability to eat, speak, and smile with confidence.

The Road Ahead: What’s Next for 3D Bioprinting in Dentistry?

The realm of 3D bioprinting in dentistry is still in its nascent stages, but the strides made so far hint at a future brimming with possibilities. As technology continues to evolve and integrate with other advanced fields, the dental industry stands on the cusp of a revolution that promises to redefine patient care. Let’s explore the potential advancements on the horizon and the role of converging technologies in shaping the future of 3D bioprinting in dentistry.

What advancements can we anticipate in the near future?

- Faster Printing Speeds: As 3D bioprinting technology matures, we can expect significant improvements in printing speeds. This will enable dental professionals to create implants, prosthetics, and other dental devices in real-time, reducing waiting periods for patients.

- Enhanced Material Diversity: Research is ongoing to discover and develop new biocompatible materials that can mimic the natural properties of dental tissues more closely. This will lead to more durable and functional dental solutions.

- Multi-material Printing: Future 3D bioprinters might be capable of printing with multiple materials simultaneously. This would allow for the creation of complex dental structures with varying material properties in a single print session.

- Integration with Augmented Reality (AR): AR could be used in conjunction with 3D bioprinting to offer real-time visualizations during the design phase, ensuring more accurate and tailored dental solutions.

- Remote Printing Capabilities: With advancements in telehealth and teledentistry, we might see the rise of remote 3D bioprinting, where dental devices are printed in one location based on scans and data sent from another.

How might the integration of AI and other technologies further enhance 3D bioprinting for dental applications?

- Predictive Analysis: AI can analyze patient data to predict potential dental issues, guiding the design and creation of preventive solutions using 3D bioprinting.

- Optimized Design Algorithms: AI-driven algorithms can assist in designing dental implants and prosthetics that are not only tailored to the patient’s anatomy but also optimized for functionality and longevity.

- Automated Quality Control: AI can oversee the 3D bioprinting process in real-time, ensuring that the printed dental solutions meet the desired quality standards and specifications.

- Integration with Robotics: Combining AI, robotics, and 3D bioprinting could lead to fully automated dental procedures, where robots carry out treatments using 3D printed tools and devices.

- Enhanced Research and Development: AI can analyze vast datasets from clinical trials and patient feedback to inform the development of new 3D bioprinting techniques and materials.

Conclusion

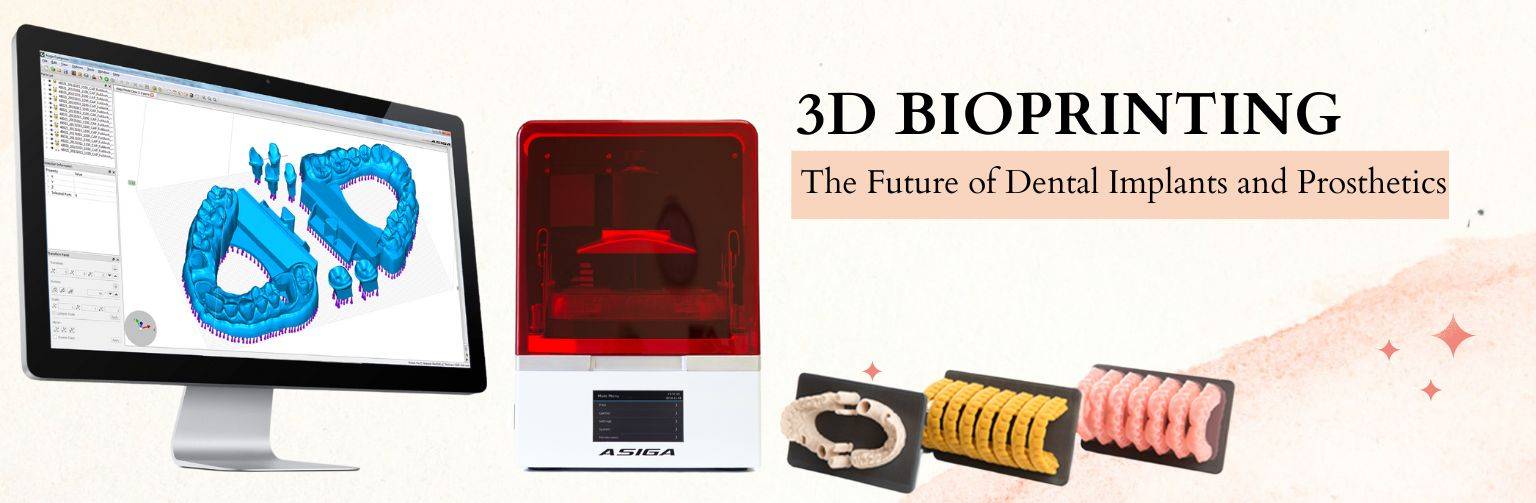

“As we delve into the groundbreaking advancements of 3D bioprinting and its transformative impact on the realm of dental implants and prosthetics, the Asiga Max 3D Printer stands out as a pivotal tool heralding this new era. This innovative printer redefines precision and efficiency in creating dental applications, ensuring that each implant or prosthetic is crafted with the utmost accuracy and quality.

With its cutting-edge technology, the Asiga Max enables dental professionals to produce intricate and customized dental solutions, tailored perfectly to meet the unique needs of each patient. The level of detail and customization possible with this 3D printer goes beyond traditional methods, allowing for more natural and comfortable dental prosthetics and implants.

Incorporating the Asiga Max 3D Printer into our practice is a step forward into the future of dental care, embracing the possibilities that 3D bioprinting brings. It reflects our commitment to innovation, precision, and excellence in patient care, ensuring that we are equipped to provide the best possible outcomes for those we serve.

As we conclude our exploration of 3D bioprinting in dental implants and prosthetics, it is clear that the integration of technologies like the Asiga Max 3D Printer is not just an advancement; it is a necessary evolution, propelling our practice into the forefront of dental excellence and patient satisfaction.”

Leave a comment