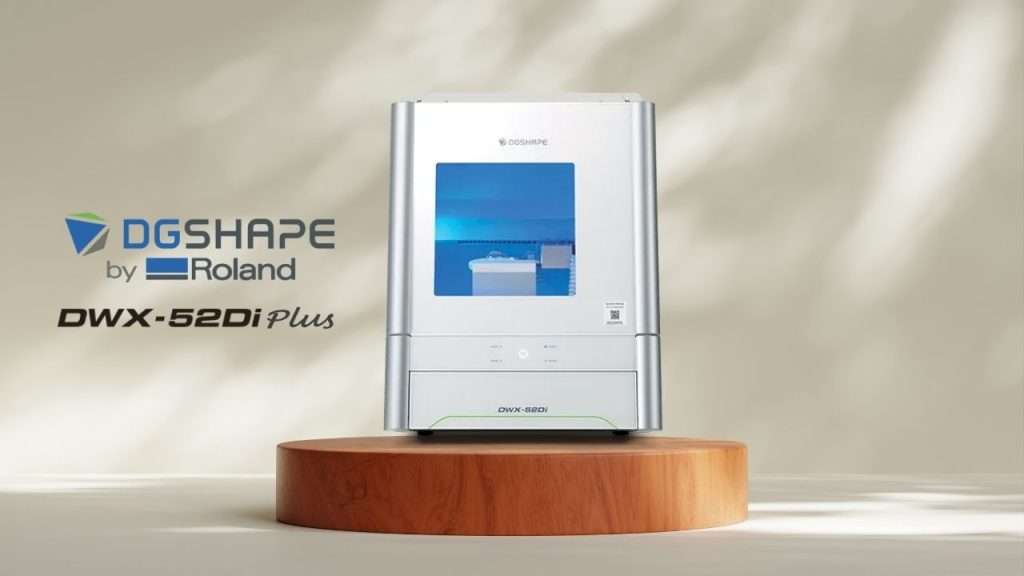

Roland DWX 52 Di Plus Dental Milling Machine

Roland DWX 52 Di Dental Milling Machine

Overview

The DWX-52Di Plus introduces a new era of precision, reliability, and affordability in dental milling. Designed for dental labs, clinicians, in-house labs, and DSOs aiming to boost their production capacity and capabilities, this model offers the renowned build quality, precision, and efficiency of DWX-52Di technology. Now available in a fixed clamp model, it provides an economical option without the added accessories, yet with increased unit capacity per disk.

Key Highlights

Key Features:

- Material Adapter Compatibility: Features a FIXED C-CLAMP, emphasizing ease of use and precision.

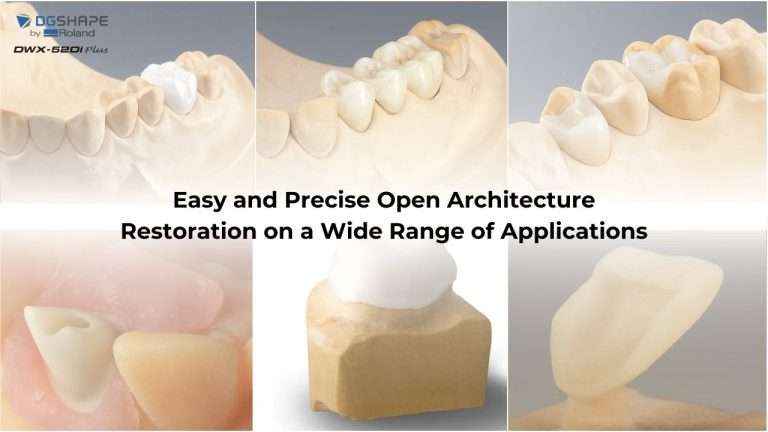

- Open Architecture Restoration: Allows for milling a wide range of applications with accuracy and simplicity. It supports various CAD/CAM software, scanners, and materials, offering flexibility and freedom in operations.

- Simplified Operation: An intuitive Virtual Machine Panel (VPanel) manages tool swapping with the intelligent Tool Control (ITC) function, conducts machine diagnostics, and ensures automatic calibration.

- User Replaceable Spindle: Enables quick and easy spindle replacement by the user, eliminating the need for technician assistance or special tools.

- 52Di Model C-Clamp Adapter: Designed for cost-effective milling, allowing up to 31 single units per material disc.

- Increased Milling Capabilities: Features a 15-station Automatic Tool Changer (ATC) and auto-adjusted air pressure for continuous milling, responding to CAM software data for optimal air volume adjustment.

- 5-Axis Milling: A ball screw-driven system enables simultaneous rotation and tilting of discs for deep undercuts and milling of large arch restorations with precision.

- Clean and Efficient Milling: Equipped with an auto-start dust collection system for cleanliness and a built-in ionizer to reduce static when milling PMMA.

Technical Specification

| Specification Category | Details |

|---|---|

| Cuttable Material | Zirconia, Wax, PMMA, and more |

| Workpiece Weight | Up to 1.87 lbs (850 g) |

| Workpiece Dimensions | Various sizes, max height 35mm |

| Number of Adapters | 6 housed |

| Operating Speed | 6 to 1,800 mm/min |

| Spindle Motor | Brushless DC |

| Spindle Speed | 6,000 to 30,000 rpm |

| Rotary Axis Travel Angle | A: ±360°, B: ±30° |

| Burs Housed | 15 |

| Attachable Bur | 4 mm diameter, 40-55 mm length |

| Compressed Air Compatibility | 0.2 MPa |

| Interface | USB |

| Control Command Set | RML-1, NC code |

| Power Requirements | AC 100 V, 50/60 Hz |

| Power Consumption | Approx. 200 W |

| Operating Noise | 70 dB(A) operation, 45 dB(A) standby |

| Dimensions (W x D x H) | 34.6 x 26.0 x 23.6 inches |

| Weight | 231.5 lbs. (105 kg) |

| Installation Environment | Specific conditions outlined |

| Included Items | Various tools, software, accessories |

| Operating System | Windows 7/8/8.1/10 |

Watch the Video

FAQ's

The DWX-52Di plus is designed for unattended production with features like a 6-slot automatic disc changer (ADC), a 15-station automatic tool changer, and other automated functionalities. This ensures powerful, efficient, and continuous dental restoration, even during non-operational hours.

The mill can process various materials, including Zirconia, PMMA, Gypsum, PEEK, Glass fiber-reinforced resin, Composite resin, and CoCr sinter metal. It offers the flexibility to load up to six discs in the ADC, allowing continuous milling in different zirconia shades and other compatible materials.

The DWINDEX software provides performance visualization, allowing users to analyze production results, gather data, and compare tool and material operation. This intelligent software contributes to efficient operation and maintenance planning for the DWX-52Di plus.

Related Products

Associated Brands